Menu

Hydrocarbon separatorCoalescent with blinding |

|

Separators > Hydrocarbon separator

Description

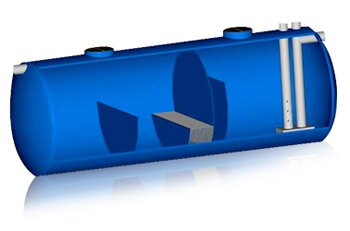

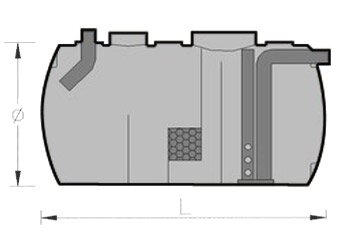

The hydrocarbon separator is necessary in all types of vehicles and machinery workshops, garages, service stations, car washes, scrap yards, etc. The purpose of the separator is to separate up the remains of mineral grease, oils, fuels, etc. Resmat hydrocarbon separator units are built to standard DIN 1999 and European standard UNE-EN 858-1 and UNE-EN 858-2, and have a reduction rate of up to 90 %. Maximum discharged 5 mg/L.

Available models

Operating Details The process begins with the decanting of the heavy materials, normally sand. As a result of the difference in specific weights between the water and the hydrocarbons, they move to the bottom and top of the tank respectively. The water is collected from the bottom of the tank and piped to the next chamber by means of coalescence, where the small drops of hydrocarbon, not separated in the first chamber due to their small volume, bind together to form larger drops. The last process involves the blinding buoy, whose purpose is to prevent the hydrocarbons getting out and to block the outlet if the maximum retention capacity is exceeded. In carwashes or in situations where discharges of hydrocarbons are accompanied by a large quantity of sand, it is essential to install a sand separator for the separator to work properly.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||